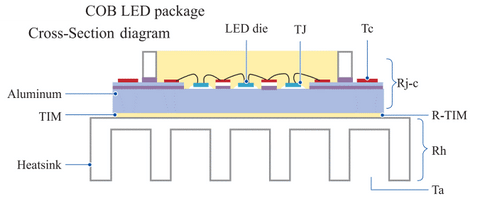

Calculate the required led heat sink the basics to do that is to understand the scheme at the right each part of the design adds up some heat due to individual thermal resistances of each material.

Cob led heat sink calculator.

A led luminaire can be seen as an electrical scheme with the thermal resistances of the led internally the interface material and the led cooler is series.

The electrical power pe vf x if or 35 5v x 0 5a 17 75w.

Below are 2 illustrations of cob leds mounted to a heat sink with a layer of thermal interface material tim in between.

In our experience it generally estimates the overall heat sink volume within 15 of a final design.

The heat sink size calculator is based on a well established equation for estimating heat sink volume during the early stages of heat sink design.

Suitable candidates include the mechatronix lpf6050 zhc.

Heat is then conducted up through the heat sink and finally is convected to the air around the heat sink by natural convection or forced convection.

The dissipated power pd pe x efficiency where the efficiency of the cob is around 32 or 17 75w x 0 68 12 07w.

This compact heat sink is 60mm in diameter and 50mm tall and it has a thermal resistance θs of 4 0 c w.

For example let s say we are selecting a heat sink for an osram prevaled core z3 1100 led cob module which is 1100 lumens.

This simple yet powerful calculator allows the rapid design and analysis of heat sinks by novices and experts in thermal analysis.